Name: Hao bin,Ni

Tel: 0769-88977096

Fax: 0769-83725800

Mobile: +86-13560850555

E-mail: 22213690@qq.com

Add: Guangdong province Dongguan City Hengli Town Town Industrial Zone, East Ring Road No. 265

QQ:

863384555

|

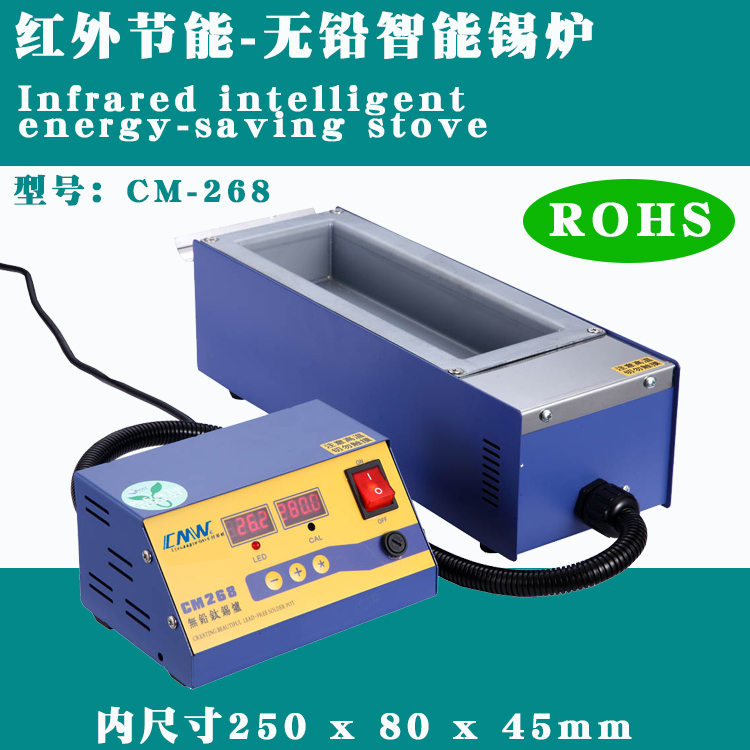

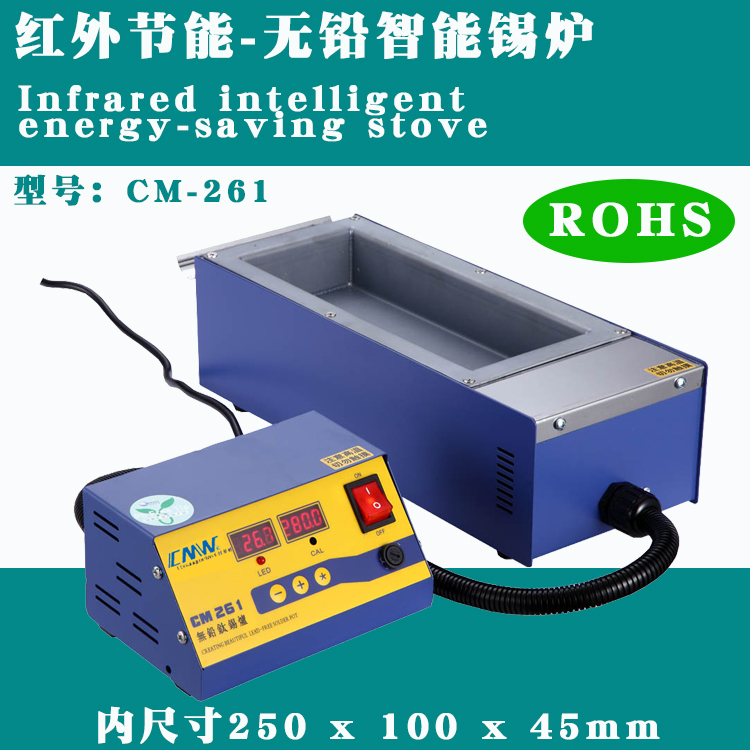

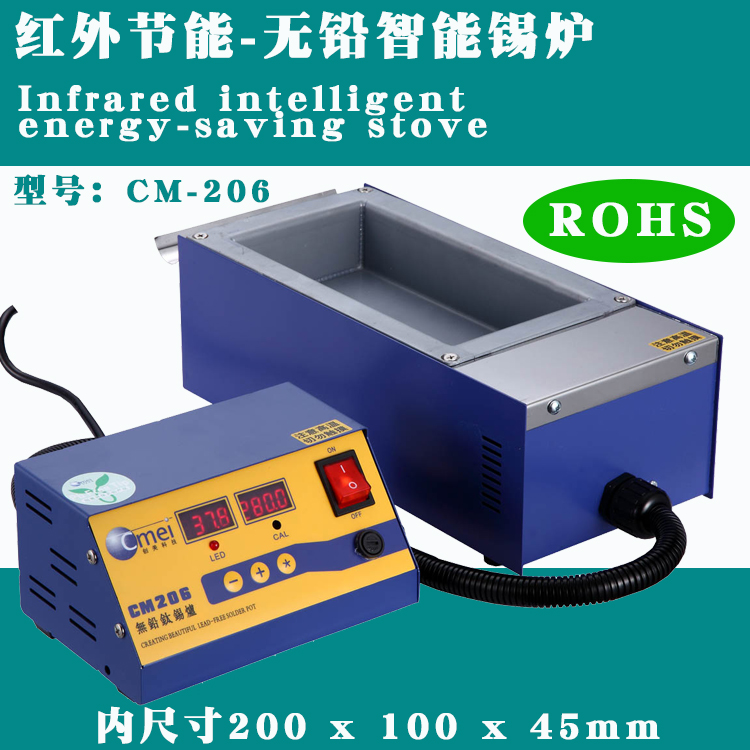

Product name : Split leadless soldering tin furnace

Item : CM268

Model : CM268

power : 1000W

temperature : 0-600

size : 250x80x45mm

|

| Details: | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

LEAD-FREE TITANIUM ALLOY SOLDERING POT Operation instruction Our Lead-free titanium alloy soldering pot passed by SGS, built-in advanced microcomputer digital control and display system, make it more safe, more steady and more accurate. It’s a good tool for electronic fields.

FEATURES: * With big power heater, only within 25minutes to reach * With advanced microcomputer digital control and double displays. make it more accurate heating and fast temperature returning capability. * The boiler made of titanium alloy, can resist high temperature, cauterization and abrasion, largely prolong the life. * With temperature setting and locking function, will not be affected by wrong operation. * The setting value will be saved for long time, and can not be affected by power on or off. With auto sleeping function, prolong the machine’s life. * With malfunction alarm.

ITEM NO. : Desk round type:

Stand type:

Desk quadrate type:

Working conditions: Working voltage: AC220±10V Working temperature: 0 Working temperature: < 90% no dew

WARNING: 1. The soldering pot must be put on the balanced and ovenproof working desk, prevent the glowing tin go out of the pot. And also take care of the hot tin and the hot body. 2. Do not put other pb items together with the lead-free soldering pot, prevent pb pollution. If cause the products do not eligible, then we won’t take on this liability. 3. It can’t be used where it will be exposed to ignitable or corrosive materials and gases. 4. If you need to move the soldering pot, please turn off the switch and move it after the pot turn cool. 5. The pot is a hot equipment, if you no need to use, please shut off the switch, and put out the plug. 6. In order to keep it safe and prolong the life, it’s better stop working after it has worked more than 12hours. 7. Do not heating the pot when it’s empty, and use the power supplier with grounding cord. 8. The pot is made of titanium which import from

OPERATION 1. Set temperature: Press the “ * ” button, the left LED will display “∟”,and the right LED will display numerical value, then press the “+” or “-”button, temperature will go up or down. Press “ * ” button, the value of temperature will be saved.

2. Microcomputer adjusting itself If the temperature has obvious discrepancy, we can adjust the inside P, I, D value, it will make the pot with accurate control, the followings are two ways of P, I, D adjusting: A. Auto adjusting Keep pressing “+” button, then press “ * “, the left LED will display “AT”; the right LED will display “_ _ _”. Then press “ – “ or “ + “ change the “_ _ _” to “AT”, this time please press “ * “ for 3 times, then the pot will begin P, I, D adjusting itself. Usually it will take for about 15-30 minutes to finish this adjusting, during this adjusting the temperature will fluctuate obviously, but it’s no wonder. Usually, we do not recommend the users use P, I, D adjusting. B. Adjust the value of P, I, D by manual (Do not advise users use this way, it’s fit for the engineers who know P, I, D very well, otherwise maybe cause bad temperature control. If really need, we just recommend the first way.) The operation as follows: Keep pressing “ + “, then press “ * “, the LED will display above (A) setting mode, press “ * “ again the LED will display the value of P, I, D. Manual adjusting just can be set the original value.

Remarks: The original of P, I, D value is: P=20, I=80, D=20; If the temperature in confusion, please set the P, I, D value as original value.

3. Calibration between display and real temperature. After the heater was replaced or the sensor was oxidated, the temperature will occur warp, the users need to calibrate the pot termly, and as the follow steps: A. Press “CAL” button (If your pot without this button, please open the front cover, there is a black button on the PCB of temperature control, that is CAL), the right LED will display OFF, keep pressing “ – “, and press “ * “ at the same time, the left LED will display “LOC”, the right LED will display “-3-“, then press “ * “ for 3 times (just this button, do not press any other buttons), the LED will display: The first time: Left “∟H”, right “ B. The warp temperature is the value to input, after finish setting, press “ * “ again, the set value will be saved. Then press “CAL” (If your pot without this button, please open the front cover, there is a black button on the PCB of temperature control, that is

TROUBLE SHOOTING: 1. Turn on the switch but no reflection, please check the fuse, and the plug. 2. The LED display setting temperature, but the pot temperature won’t go up, it means that the heater is open circuit. 3. The pot display “Err” when the power switch is turned on, it means that the sensor is open circuit.

|

| Related Products : |

ESD tweezers

ESD tweezers

Lead free bench round high temperature furnace

Lead free bench round high temperature furnace